|

Dynamic Graphics Process Simulation

Software,

VC++ Source Code Component Solution

Product Tour

E-XD++ and UCCDraw product walkthrough

Screenshots

Applications built on E-XD++

ToolKit

Screenshots

Applications built on E-XD++

ToolKit

Product feature comparison

Product feature comparison

The quick and simple way to building

Dynamic Graphics Process Simulation Software with

Visual C++, and the

.NET platform

Download

this Dynamic Graphics Process Simulation & Hmi Sample 0 Download

this Dynamic Graphics Process Simulation & Hmi Sample 0

UCanCode provides a complete set of

services, consisting of design tools and

a software

development kit (SDK), for developers who want to create a user

interface for industrial monitoring and process control drawing

Dynamic Graphics, Process Simulation applications. These displays feature

highly customized graphical objects that connect to underlying real-world

data.

Developers prefer UCanCode's solutions

because they are easy to use, completely customizable, and can deploy to

both the desktop and the Web. UCanCode is the industry’s leading

real-time SPC software, automating quality data collection and

analysis

Add Diagrams and

Dynamic Graphics Process Simulation to your applications. E-XD++ Diagrammer brings accurate and

intuitive diagrams and dashboards to your c++ desktop applications. It

offers a comprehensive set of tools, components and graphic objects for

creating visualization, editing and monitoring Windows applications.

It is very quickly and

easily to use E-XD++ to build any

Dynamic Graphics, Process

Simulation Software:

The following is another sample on

Dynamic Graphics Process Simulation

Application:

State 1:

State 2:

State 3:

1.

Design the

Dynamic

Graphics Process Simulation

symbols:

With E-XD++ full edition, there is a shapedesigner

application shipped, with this diagramming tool, you can

use many advance features to build any kind of

Dynamic Graphics Process

Simulation Software

symbols, The Symbol Editor is an interactive

point-and-click editor that creates, edits and organizes

intelligent symbols to populate a user interface, as below:

When one composite symbol

is designed, just use Copy/Paste to place it within the

toolbox window at left side. These

Dynamic Graphics Process Simulation Symbols will be ready for use in

future. The Shape Designer offers graphics editing

capabilities and is fully interoperable with authoring

tools, such as Adobe Illustrator or Inkscape, to ensure

that the visual elements of the symbol are as appealing

as possible. It then adds dynamics to graphics with

rules describing how the elements of the symbol will

react to data changes. For example, rules can define the

alarm conditions that will cause a part of a factory

symbol to blink, or how far a needle on a rotary gauge

will rotate. The newly created symbol can then be

cleanly organized in palettes and reused by the other

design tools. By default, the Shape Designer contains

palettes of fully functional symbols for diagramming and

monitoring applications, such as gauges, buttons,

meters, dials and more.

What is a

"Symbol?"

A symbol is a self-contained graphic object that

represents a physical or conceptual element in the

underlying application. For example, symbols can

represent trucks, factories, network elements, dials or

gauges.. They have built-in behavior and an exposed

interface, like a graphic VC++ control. When an

application executes, its symbols connect to real-world

objects and are "data-aware"—when the underlying data

changes in a meaningful way to the user, the overlying

symbols change their appearances. For example, if a

component in a data network reaches a pre-defined

critical threshold, the symbol associated with it might

display a red alarm. Or if an airplane has moved, then

its symbol will move on a map display.

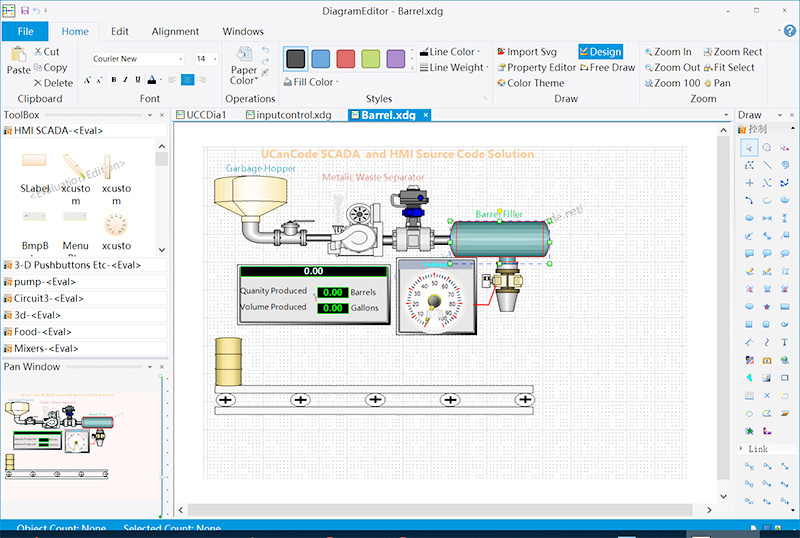

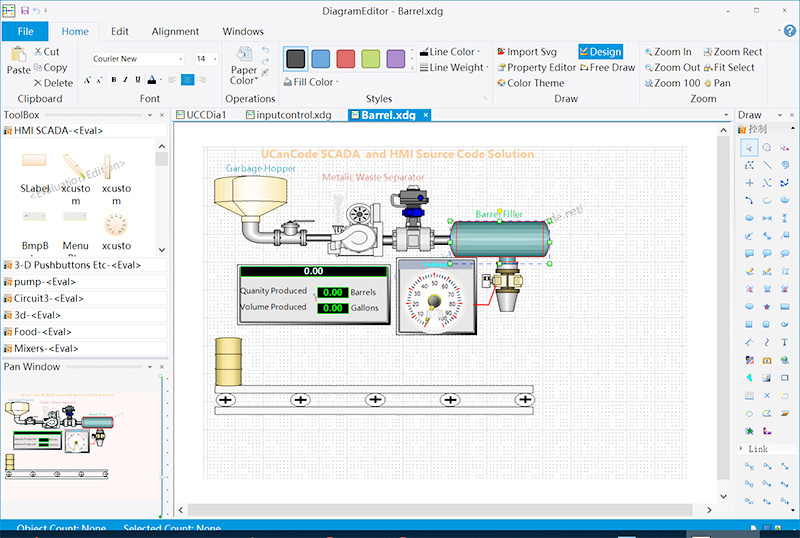

2. Design

Dynamic Graphics Process

Simulation Software Screen:

With E-XD++ full edition,

there is also a ready to use

Dynamic Graphics Process Simulation Screen design tool shipped, with this

tool, you can use any symbols within the toolbox window

at left side to build any screen as you want, just drag

and drop, very simple and easy:

Diagram Editor is

well-suited for defining the look and feel of

applications that must automatically create a

diagram—such as a business process, a network typology,

a workflow, a dataflow, or entity-relational

diagrams—from a data source.

If you want to identify any

shape on the screen, just use the following dialog to

define some key value. There are three key values that

can be used to do this work, as below:

We change it's key value 1

to K2.

After one

Dynamic Graphics Process

Simulation Software

Screen is finished, you can save it to a xdg file. You

can design as many screen as you want.

3. Building your

Dynamic Graphics Process Simulation Software:

With full edition of E-XD++

Visualization Component, there is an appwizard that will

help you building a base framework of

Dynamic Graphics Process

Simulation Software without

written a line of codes, after the base framework of

your application is finished, you can import any XDG

files into your application, (Please remember the

resource type must be XDGRes), to load a

Dynamic Graphics Process

Simulation Screen just

call the following codes, it is very easy:

LoadXdgFromResource(IDR_MAIN,

_T("XdgRes"), FALSE);

In fact, this line of code

can be called at any place if you want to load any new

screen at any time.

4.

Update the screen with data:

Mostly we can use the WM_TIMER of CWnd to recieve the

data and refresh the Dynamic

Graphics Process Simulation

Screen, if you want to update only one shape, just call

UpdateControl of this shape, but if you want to update a

list of shapes one time, we recommend you to call

UpdateShapes, this will works more effective, below is

the sample codes:

void CAutoDemoView::OnTimer(UINT nIDEvent)

{

// TODO: Add your message handler code here and/or call default

if(nIDEvent == ID_TIMER_ID)

{

CFODrawShapeList lstUpdate;

int xx0 = rand() % 20;

int xx1 = rand() % 18;

int xx2 = rand() % 25;

int xx3 = rand() % 16;

int xx4 = rand() % 12;

int xx5 = rand() % 21;

if(pK1 != NULL)

{

CString strText;

strText.Format(_T("%u mcA"), xx0 * xx1);

pK1->SetLabelText(strText);

lstUpdate.AddTail(pK1);

}

if(pK2 != NULL)

{

CString strText;

strText.Format(_T("%u C"), xx0 * xx2);

pK2->SetLabelText(strText);

lstUpdate.AddTail(pK2);

}

if(pK3 != NULL)

{

CString strText;

strText.Format(_T("%u Nm/h"), xx0 * xx3);

pK3->SetLabelText(strText);

lstUpdate.AddTail(pK3);

}

if(pX1 != NULL)

{

CString strText;

strText.Format(_T("%u"), xx0 * xx4);

pX1->SetLabelText(strText);

lstUpdate.AddTail(pX1);

int nValue = xx0 * xx4;

if(nValue > 200)

{

pX1->SetBkColor(RGB(255,0,0));

}

else if(nValue > 100)

{

pX1->SetBkColor(RGB(255,255,0));

}

else

{

pX1->SetBkColor(RGB(0,0,0));

}

}

if(pX2 != NULL)

{

CString strText;

strText.Format(_T("%u"), xx0 * xx5);

pX2->SetLabelText(strText);

lstUpdate.AddTail(pX2);

int nValue = xx0 * xx5;

if(nValue > 200)

{

pX2->SetBkColor(RGB(255,0,0));

}

else if(nValue > 100)

{

pX2->SetBkColor(RGB(255,255,0));

}

else

{

pX2->SetBkColor(RGB(0,0,0));

}

}

if(pX3 != NULL)

{

CString strText;

strText.Format(_T("-%u"), xx1 * xx5);

pX3->SetLabelText(strText);

lstUpdate.AddTail(pX3);

int nValue = xx1 * xx5;

if(nValue > 200)

{

pX3->SetBkColor(RGB(255,0,0));

}

else if(nValue > 100)

{

pX3->SetBkColor(RGB(255,255,0));

}

else

{

pX3->SetBkColor(RGB(0,0,0));

}

}

if(pX4 != NULL)

{

CString strText;

strText.Format(_T("%u"), xx2 * xx3);

pX4->SetLabelText(strText);

lstUpdate.AddTail(pX4);

int nValue = xx2 * xx3;

if(nValue > 200)

{

pX4->SetBkColor(RGB(255,0,0));

}

else if(nValue > 100)

{

pX4->SetBkColor(RGB(255,255,0));

}

else

{

pX4->SetBkColor(RGB(0,0,0));

}

}

if(pX5 != NULL)

{

CString strText;

strText.Format(_T("%u"), xx2 * xx4);

pX5->SetLabelText(strText);

lstUpdate.AddTail(pX5);

int nValue = xx2 * xx4;

if(nValue > 200)

{

pX5->SetBkColor(RGB(255,0,0));

}

else if(nValue > 100)

{

pX5->SetBkColor(RGB(255,255,0));

}

else

{

pX5->SetBkColor(RGB(0,0,0));

}

}

if(pX6 != NULL)

{

CString strText;

strText.Format(_T("%u"), xx3 * xx5);

pX6->SetLabelText(strText);

lstUpdate.AddTail(pX6);

int nValue = xx3 * xx5;

if(nValue > 200)

{

pX6->SetBkColor(RGB(255,0,0));

}

else if(nValue > 100)

{

pX6->SetBkColor(RGB(255,255,0));

}

else

{

pX5->SetBkColor(RGB(0,0,0));

}

}

if(pChartShape != NULL)

{

pChartShape->UpdateData(xx0 * xx1, xx0 * xx2, xx0 * xx3);

lstUpdate.AddTail(pChartShape);

}

if(lstUpdate.GetCount() > 0)

{

UpdateShapes(&lstUpdate);

}

}

else

{

CFODrawView::OnTimer(nIDEvent);

}

}

If you want to handle the

click event, you can DoButtonClickEvent to do that.

That's all, below is the

running - time mode of this sample.

- Dynamic

Graphics Process Simulation

Software Component

Process

Control Diagram

Full

VC++ Source Code

Real - time

Drawing

Very easy to use shape Designer

SVG Import

With E-XD++

Component,

you can add advanced Dynamic Graphics Process Simulation functionality to your

applications. The E-XD++ Library is a 100%

VC++ data

rendering and visualization system, built

specifically for Visual Studio .NET and designed to

bring your User Interface to the printed page. Now you

only need a few days for building a very powerful label

print or report print application.

The leader in visualization component -- FULL

VC++ Source Code Shipped!

XD++ Diagrammer Suite is the the world’s

leading VC++ and .NET visualization component. Renowned for incredibly rich

graphics, XD++ helps thousands developers build applications that offer

unparalleled functionality. Outstanding productivity lowers project risk and

reduces maintenance headaches. With 20 years of dedicated research and

development, UCanCode leads the market for visualization technologies,

providing outstanding customer support.

Powerful, flexible, and

easy to use Diagram Components.

Powerful and flexible enough to create diagrams exactly the way you want

them to appear. So easy to use that you will be able to prototype your

application in just a few minutes.

Feature rich.

With features such as automatic layout, multiple layers, collapsible

sub-graphs, snap-to connection points, XML, SVG, and more, E-XD++ Have the

power and flexibility you need to create sophisticated diagrams, quickly and

easily. Events such as click, double-click, hover, select, rubber-band

select, copy, delete, resize and move are supported. Operations such as

drag-and-drop, unlimited undo/redo, and clipboard operations are common and

complex, and are expected by today's sophisticated users. it full supports

importing ArcGis, SVG and DXF File format.

Performance and

Scalability.

UCanCode E-XD++ Capable of handling many thousands of nodes and edges, up to

hundreds of thousands depending upon the complexity of the nodes you wish to

draw and the operations you wish to allow. Our graphical classes are

extremely lightweight objects enabling outstanding performance.

Save Time and Money and gain Reliability.

A diagram is worth 1,000 words, and E-XD++ is shipped with more than 500,000 lines of well designed and well tested code! It is used by hundreds of the world's most quality conscious companies. It will saves you thousands of hours of complex coding and years of maintenance.

Download

this Dynamic Graphics Process Simulation & Hmi Sample Download

this Dynamic Graphics Process Simulation & Hmi Sample

The

VC++ source codes of this sample is shipped with E-XD++

Library Enterprise Edition,

order it now.

News:

1 UCanCode Advance E-XD++

CAD Drawing and Printing Solution

Source Code Solution for C/C++, .NET V2025 is released!

2

UCanCode Advance E-XD++

HMI & SCADA Source Code Solution for C/C++, .NET V2025 is released!

3

UCanCode

Advance E-XD++ GIS SVG Drawing and Printing Solution

Source Code Solution for C/C++, .NET V2025 is released!

Contact UCanCode Software

To buy the source code or learn more about with:

Next-->

Next-->

HMI

and

Graphics Software ToolKit Solution from

UCanCode

-- Full Visual C++ Source Codes

|

|