Overview

This code is a working example of a

PID

(Proportional, Integral, Derivative)

control.

This type of a

control

is used when

processes

change due to inertia. (A car's cruise

control is a

PID

controller.)

The PID

algorithm is surprisingly simple, and can be

implemented in five lines of code. There are three

constants that must be determined in order to shape

the control's

output. The three constants as well as the set point

and sampling interval can be changed in real time.

The resulting shape of the output will be displayed

in a strip chart.

How are PID loops

used?

Many real

world processes

build up over time.

When you step on the accelerator, your car moves

slowly, then faster, and faster still, until you let

off the gas pedal. As you speed up, you press the

gas pedal less, then a little less, then even less,

until you reach the speed limit. Unlike the digital

world where things are either “on” (1) or “off” (0),

real processes

have varying degrees of “on”. In the driving

example, how much the accelerator is turned “on”

depends on the car's current inertia and how

different the car's speed is from the speed limit.

Controlling

such a process

with inertia can be done with only five lines of

code. But, just like learning to drive, it takes

practice to know if you are starting too quickly, or

if you'll overshoot the speed limit.

Cruise

control

is one example of a PID

control loop.

To calculate the output, it needs three factors. The

first, (P), is the difference between the current

speed and the desired speed. The second, (I), is the

sum of the differences over time. And, the third,

(D), is the rate of change between sampled

differences. Each factor is scaled by a gain

constant; they are refered to as Kp, Ki, and Kd. The

value of these gain constants determines how

responsive the output will be. If the Kp, Ki, and Kd

values are too high, the output (car's speed) will

far exceed the set point (speed limit). Set too low,

the output may never reach the set point (like

driving 40mph on the highway).

Code implementation

In the real

world, a

process

updates constantly. In order to

simulate this

action, a timer is used to run an equation that

models the

process.

From a second timer, the

PID

control

algorithm samples the

process

value at a rate slower than the

process

model updates. The “Process

Value” or PV timer should run at least twice as

faster than the “PID

control”

timer. In the application, the PV timer runs every

17ms, and the PID

timer runs every 100ms.

The PV timer (tmrPV)

tick event handler runs the following code:

Collapse

Collapse |

Copy Code

private void tmrPV_Tick(object sender, EventArgs e)

{

PV = PV + (output * 0.20) - (PV * 0.10) + noise;

}

The PID

control

timer (tmrPID_Ctrl)

tick event handler runs:

Collapse

Collapse |

Copy Code

private void tmrPID_Ctrl_Tick(object sender, EventArgs e)

{

error = setpoint - PV;

integral = integral + (error * Dt);

derivative = (error - preError) / Dt;

output = (Kp * error) + (Ki * integral) + (Kd * derivative);

preError = error;

}

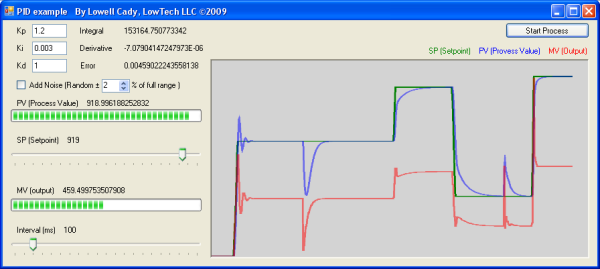

Take a look at some typical output shapes

In the images below, the green line is the set

point, the blue line is the input (or

process

value), and the red line is the output (or

manipulated value).

Correct

control

signal. All three gain constants are set

correctly.

Overshoot. Integral constant too high.

Undershoot. Integral constant too low.

Ringing. Integral and Proportional gain

constants too low.

Noise (under

control). All three constants are set

correctly.

Noise (not

controlled). Derivative gain constant too

high.

Code modifications

you might consider

This example works for modeling any

process

that has inertia. The

process

being modeled here is a car's cruise

control.

In order to adapt the code to model a

process

other than cruise

control, the equation in the PV timer tick

event handler should be changed.

I use PID

loops for electric furnace

control.

In furnace

control,

thermal mass is measured by sampling temperature.

Better PID loop

tuning results in efficient energy use. The code

currently in the PV timer tick event handler is

pretty close to a furnace equation. You can modify

the equation to fit the system you want to model. As

a rule of thumb, use the following equation:

Collapse

Collapse |

Copy Code

ProcessValue = ProcessValue + (output * efficiency) – loss

In a real cruise

control,

there are limits on how much the output can change

from sample to sample. This example does not include

any way to limit the output's magnitude of the

change. Such code might look like:

Collapse

Collapse |

Copy Code

if ( (output – outputLast) > maxChange)

output = outputLast + maxChange;

else if ( (outputLast – output) > maxChange)

output = outputLast – maxChange;

outputLast = output;

The noise that can be added to the signal is not

representative of anything your car might encounter.

(It is really just a model of electrical noise.)

Noise to a car's cruise

control

might be something like a hill, or a gust of wind.

Both of those examples have a lower frequency than

our noise. Since the noise is created in its own

timer event handler, you can change the interval of

the noise to change its frequency. You could also

change the noise equation to model the effects of a

hill, or even a chilling arctic blast.