1

COM/OLE

applications are

widely used in

Industrial

Automation and

Process Control

domains. Since not

many programmers are

aware of these

technologies, I

thought to share my

experience in

OPC and most

developers would

love to expand their

knowledge about

COM/OLE application

areas.

The goal of

article: Give

simple &

understandable

overview of

OPC. More

detailed information

and specifications

can be downloaded

from

OPC

Foundation and

websites mentioned

in Resources

section.

So first, about

the above diagram...

Theory about

Figure 1:

On left-bottom

is a hardware

device. It could

be a

PLC

(programmable

logic

controller), a

temperature

sensor, roller

belt controller,

or just about

any industrial

device. Central

part is the

OPC

server. Right

side is the

client that

wants to

operate the

device. The

OPC

Server gives out

standard COM

interfaces so

that any client

aware of these

OPC

Interfaces

can interface

with server and

operate the

device -

without

programming

device driver

for that

hardware.

Hardware can be

as varied as

OPC

server

can

handle and

clients can

still read and

write from this

hardware.

Now back to

our

OPC course.

This article gives

an overview of

OPC and

covers following

topics. Source code

is not available,

since most of server

code is specific to

hardware. And client

would still need a

server to connect

to. But yes, if you

want to experiment

with

OPC, check

out the Resources

section below.

History of

OPC

In 1996, a group

of companies

Rockwell Software,

Intellution, et. al.

came together to

form a consortium

that defined a

standard for process

control.

SCADA and

similar

standardization

efforts were being

made at that time in

process control and

automation industry.

This group created

an initial draft

that was based on

Microsoft's Object

Linking and

Embedding (OLE). It

was called OLE

for Process

Control

(OPC).

OPC

Foundation

publishes

specifications and

manages everything

that goes into

OPC

technology.

Today more than

300 companies are

part of

OPC

Foundation.

Microsoft, GE,

Siemens, Rockwell,

ABB, Ford, Honeywell

and more are members

that actively

contribute and

consume

OPC

technology.

In 2005,

OPC

Foundation released

OPC Unified

Architecture draft.

There are

predecessor drafts

released before -

OPC HDA,

OPC DX,

OPC AE,

OPC Commands,

OPC Security.

We will briefly

study them in this

article.

By now, you must

have a question in

your mind. Let me

answer it below...

Why do we need

OPC? its

Benefits

I was also a

first timer to

OPC (coming

from varied

experience in

DevTools, eLearning,

CAD/PLM,

Multimedia), and had

no clue as to why do

we need it. I found

that learning it

through a case study

was very helpful, so

I am going to do the

same for you. To

understand the need

for standardization

in process control

industry, let me

give you an actual

case study performed

by a giant

organization in

Petrochemicals

business.

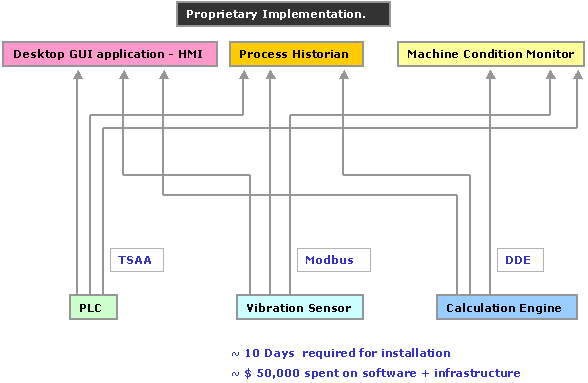

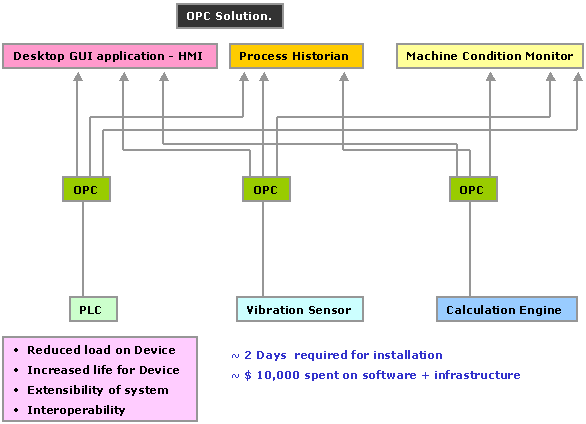

Refer to figure

2. It shows the

devices and software

application that

were in action on

this particular

petrochemical plant.

PLC, Vibration

sensor, and

Calculation engine

work on different

communication

protocols - TSAA,

Modbus, and DDE. So

the software

applications that

need data from these

devices also need to

be aware of TSAA,

Modbus, and DDE

protocol.

Additionally each

device needs to

serve all the three

applications. The

process historian,

GUI application

providing human

machine interface

and the machine

condition monitor

all communicating

with all devices

results in a

complexity. This

deployment took the

company around 10

days. And its cost

was approximately US

$ 50,000.

Now, someone like

me :) came to them

and said, "hey guys,

why don't we think

smart and implement

as in Figure 3?".

Observe the reduced

complexity. Now all

software

applications talk

only to the

OPC Servers.

And all devices also

respond only to the

OPC server.

OPC Server

provides the

Black Box for

software

applications around

hardware.

The new

implementation took

just 2 days to

deploy and cost

incurred was

approximately US

$10,000. They could

have eliminated 2

OPC servers

as well and

implemented device

drivers right inside

a single

OPC server.

This is a tradeoff

and off the shelf

OPC servers

may have standard

protocols support

like DDE, Modbus and

TSAA.

As you observed

correctly, the

benefits are:

-

Reduced load

on device.

-

Scalability

of system has

increased.

-

OPC

server provides

caching of data.

-

Client

applications

need not know

hardware

protocol

details.

-

Increased

life for device

(it need not

serve multiple

clients

anymore).

-

Interoperability

(Unix/Linux and

Windows - both

platforms are

supported by

OPC)

-

Standardization

Now that you have

some insight into

OPC benefits

and history, let's

take one step ahead

to understand

OPC

terminology and

concepts.

OPC Concepts

& Terminology

OPC

specification

defines a consistent

terminology to

identify various

entities involved.

The best analogy to

OPC way of

data representation

is that of a file

system hierarchy.

OPC calls it

as

OPC Address

Space. Within this

address space every

entity can be

uniquely identified

by its "full-path".

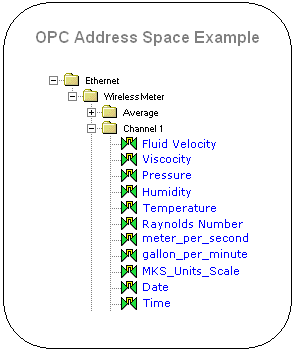

For example, refer

to figure 4.

OPC Address

Space is

hierarchical. It

starts with a root.

Then there are

logical

folders

and

sub-folders.

Leaf nodes are

OPC Items or

Tags.

Generally your

sensors and

actuators form the

leaf nodes. This is

an important point

to understand and we

will spend some time

on it. For example,

you have a device

that can sense

temperature,

Pressure, and

Humidity. Then these

attributes are

generally mapped as

leaf nodes under

some

folder-subfolder

hierarchy. We will

see what that

hierarchy can be in

a moment. If you

have an actuator

(say,

Turn_ON_Boiler),

then that also

becomes a leaf node.

You can write to

Turn_ON_Boiler

values of 1 or 0 for

example, and

necessary action

will be taken - of

course we just

assumed that your

hardware control

mechanism behaves

this way. You can

read from

Temperature

to know sensed

value.

Hope we are all

clear till this

point. Now let's

understand this

"logical" folder

stuff. The logical

folders and

sub-folders are used

to represent state

of your Industrial

Automation system.

This configuration

can actually map to

some physical

configuration or

even geographical

setup. Let's spend

some time to

understand this one

as well. For

example, in this

diagram we have an

ethernet

communication

channel to which a

wireless meter is

connected. And

within wireless

meter, there are two

classes "Average"

and "Channel1".

These folders and

sub-folders are very

effective means of

grouping your

process control

parameters and

values.

This address

space is "published"

to all clients of

OPC server.

The

OPC clients

can be simple

spreadsheets like

Excel, process

historians that keep

record of data

coming from various

industrial plant

entities. Every

client can create a

logical entity

called as

group

inside

OPC server.

Each

OPC Group

can contain a set of

OPC Items.

Synchronous &

Asynchronous

OPC Item

reading

OPC

specification

supports synchronous

as well as

asynchronous reading

and writing on

hardware devices.

Since not all

hardware device

operations are

fast-enough, the

asynchronous

mechanism of reading

and writing to a

device comes very

handy.

COM Interfaces &

Component Categories

Well, so now

suppose you wish to

write your first

OPC client.

If you were

developing a client

that runs on local

machine as that of

server, and if you

were aware of all

OPC Server

ProgIDs, then we

would not have any

worries. But since

that is not

possible, we need an

enumeration

mechanism. Following

is an enumeration

mechanism.

Collapse

|

Copy Code

Collapse

|

Copy Code

<font size=2>OPC Component Categories

Enumeration issue is addressed by requiring OPC servers to implement

component categories. For example, all servers that are OPC DA 1.0

(more about this in later sections) compliant implement COM category

with CatID {63D5F430-CFE4-11d1-B2C8-0060083BA1FB}. Similarly the

servers compliant with OPC Data Access 2.0 implement category with

CatID {63D5F432-CFE4-11d1-B2C8-0060083BA1FB}.</font>

So

OPC

Foundation

distributes a

Windows Service

called as

OPCEnum.

Collapse

|

Copy Code

Collapse

|

Copy Code

<font size=2>Enumerating OPC Servers

OPCEnum.exe runs as a Windows Service and provides enumeration

functionality. Using OPCEnum, the client applications can query

available OPC Servers on local as well as remote networked machines.

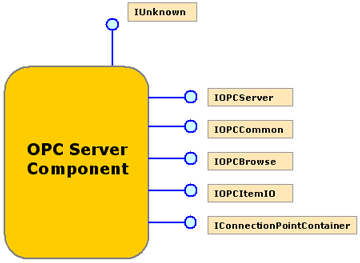

Now let's look at

server component

interfaces.

There are various

COM interfaces that

OPC Server

must support

according the

OPC

Specification

compliance required.

These basic

interfaces have

specific

functionality.

IOPCBrowse

This interface has

methods that allow

browsing

OPC Address

Space. Client can

query level by level

folders and

subfolders till the

leaf nodes. The

hierarchy looks like

shown in

figure 4.

IOPCItemIO

Interface is used

for performing

OPC Item read

and write

operations.

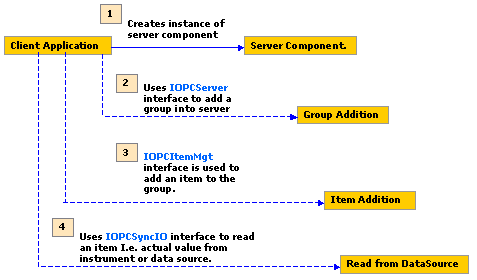

Now let's

understand how

OPC Client

interacts with the

OPC Server.

Important steps

involved are

summarized in figure

6, below.

I know you must

still be wondering

about this

OPC Group

term. Let's spend

some time

understanding it.

Every client when

opens a session with

OPC Server,

needs to create a

logical group of

items that it wants

to read or write.

Client can maintain

multiple groups.

Each group is given

a unique name and

has following

attributes:

-

Update rate

[milliseconds]

at which the

values of items

are read.

-

Active or

In-active Flag

[Boolean] only

if group is

active that the

items are

processed.

-

Deadband [%]

variations

inside this band

are considered

NULL.

-

IO Mode

[Synchronous/ASynchronous]

all operations

performed are

either sync or

async.

-

Time Bias

[time] local

time band with

respect to GMT.

The

OPC Group

component supports

following

interfaces.

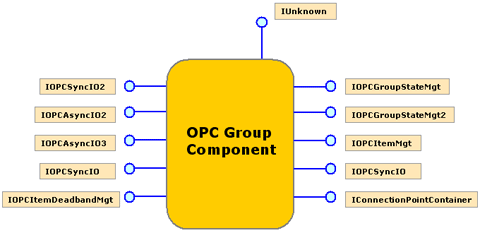

Figure 7.

As you may have

identified these IOPCSyncIO

etc interfaces that

are relevant for

synchronous and

asynchronous

OPC Item read

and write

operations.

OPC Group

Components also

support connection

point container for

events that are used

for client

notifications. At

least you have some

idea by now that

OPC is just

another COM

application in

action - just that

it is a standard

meaning all

OPC Clients

and

OPC Servers

are bound by design

contract.

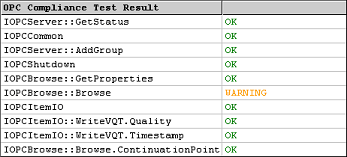

OPC

Foundation provides

compliance test

applications. Using

these suites one can

execute certain

number of test cases

on

OPC Server

and determine their

compliance to

particular

OPC

Specifications.

There are several

OPC

specifications

available (explained

in next section). A

typical compliance

report looks like as

shown in figures 8 &

9.

Figure 8.

Figure 9.

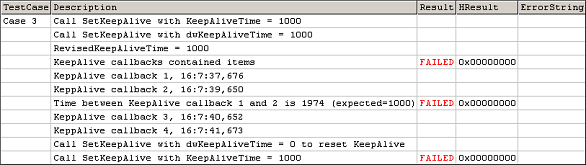

OPC

Compliance Test

Suite also supports

testing for

performance whereby

the

OPC Server in

question is loaded

with multiple items

read and write

requests. These

determine time

required per item

operation and also

passed and failed

test cases. Once

compliance is

achieved, the report

can then be uploaded

to

OPC

Foundation web site

for public

reference. So that

customers buying

OPC Server

from a particular

vendor can make sure

that the server is

compliant to a

particular

specification and

may meet their

integration need

with other software

packages used on the

plant.

OPC

Foundation is

responsible for

maintaining and

releasing new

specifications. It

is a body made up of

industry experts,

companies that

produce

OPC products

and organizations

that consume

OPC products.

So far

OPC

Foundation has

released following

specifications.

-

OPC-DA

(Data Access)

Provides access

to real-time

data. We can

query most

recent values of

temperature,

pressure,

density,

acceleration,

and other types

of process

control data

from

OPC-DA

server.

-

OPC-HDA

(Historical Data

Access) Used

to retrieve

historical

process data for

analysis. This

data is

typically stored

in archives,

databases or

remote telemetry

systems.

-

OPC-AE

(Alarms &

Events)

OPC AE

servers are used

to exchange and

acknowledge

process alarms

and events.

-

OPC-DX

(Data eXchange)

Defines how one

OPC

server exchanges

data with other

OPC

servers.

-

OPC-XML

(XML Data

Access)

Defines schema

and data

representation

format based

upon XML

standard. Makes

it possible to

share &

manipulate

process control

data across all

operating

systems –

Windows, Unix,

Solaris, etc.

-

There were

several efforts

put onto -

OPC

Security,

OPC

Batch,

OPC

Commands,

OPC for

ERP.

Most recently

OPC

Foundation has

released a draft for

OPC Unified

Architecture

that attempts to

provide even more

integration of

process control data

and software with

other industrial

software systems

like ERP.

There are plenty of

resources available

on the web about

OPC.